OVERVIEW

Hybrid Diamond x U.D. Carbon Cantilever.

A World First Hybridised Design.

The cartridge of a record player is the source of everything that is heard. The geometry and material design of the body of the cartridge is critical to its performance.

Wilson Benesch’s expertise in cartridge design dates back to the first decade of the company’s product development. During this period, Wilson Benesch designed and developed a range of cartridges that included the Matrix, the Ply, the Carbon and the Analogue. The development of the new TESSELLATE Ti Cartridges builds upon the lessons learned from the original Wilson Benesch cartridge range, which were pioneering in their use of carbon fibre technology. Now, in 2024, Wilson Benesch introduces a new range of cartridges that are equally groundbreaking, this time leveraging state-of-the-art materials and manufacturing technologies, including titanium alloy and selective laser sintering.

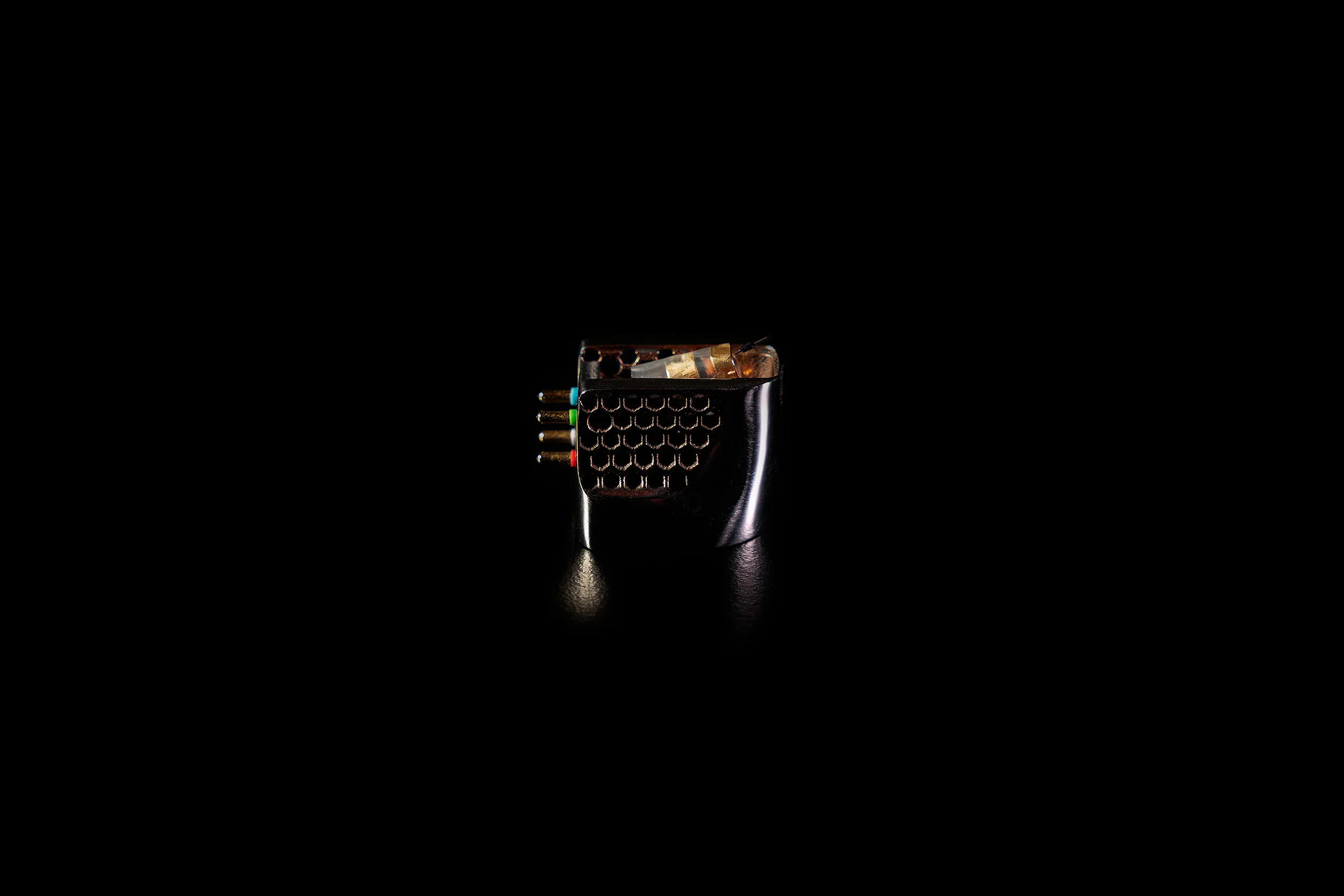

GEOMETRICALLY OPTIMISED SELECTIVE LASER SINTERED TITANIUM BODY

When selecting a material for an analogue cartridge body, the optimal material characteristic is a balance between low mass and high stiffness. In this respect, titanium and aluminium offer ideal properties. However, the choice of material is only the starting point; a designer must also consider the geometry of the structure and how the cartridge body will be manufactured.

In the TESSELLATE Ti Cartridge range, Wilson Benesch has utilised the latest selective laser sintering (SLS) manufacturing technology to create a cartridge body unlike anything seen before. Selective Laser Sintering is an additive manufacturing (AM) technology that uses high-power lasers to sinter powdered titanium alloy, forming a complex three-dimensional component layer by layer.

The image below shows a scanning electron micrograph of a Starling’s skull bone tissue, it can be used to demonstrate the biomimetic principles of topology optimisation in the tessellated structures of the cartridge body shown next to it. The internal bone structure has evolved to optimise support and strength while maintaining minimal weight. [Photo credit: Steve Geschmeissner / Science Photo Library]. Link. The same principles have been applied during the design of the TESSELLATE Ti Cartridge body and made possible through use of State-of-the-Art manufacturing technology.

Wilson Benesch partnered with Renishaw PLC, a specialist and leader in SLS AM technology, during the development of the TESSELLATE Ti Cartridges and the GRAVITON Ti Armwand. The result is a highly optimised cartridge body with a tessellated, semi-open architecture.

Wilson Benesch has achieved unprecedented levels of stiffness, low mass, and energy damping within the TESSELLATE Ti Cartridges. There is zero material redundancy in the TESSELLATE Ti Cartridge body; nothing is present that does not need to be.

The TESSELLATE Ti Cartridge body features a semi-open architecture, a design informed by extensive research and development undertaken by Wilson Benesch during the creation of its original cartridge line in the 1990s. Over successive years, Wilson Benesch developed four cartridges within this initial range, discovering that the structures directly adjacent to the cantilever played a critical role in the cartridge’s sound quality. This understanding was clearly reflected in the design of the carbon fibre headshell used in the Analogue Cartridge, and later in the Carbon Cartridge. The Carbon Cartridge featured a larger opening where the cantilever protruded, and Wilson Benesch eliminated all flat surfaces in the headshell geometry around the cantilever, opting instead for curved surfaces. These curves reduced reflected energy from the cantilever during use, thereby minimising microphonic effects. This research directly informed the development of the semi-open architecture found in the titanium structures of the TESSELLATE Ti Cartridges.

The semi-open, super-stiff titanium architecture of the TESSELLATE Ti Cartridges represents the optimal geometric form and design, incorporating all the lessons learned from previous work. The tessellated titanium structure adds significant stiffness, with curves integrated wherever possible to further enhance the cartridge body’s rigidity. Importantly, this stiffness is complemented by high levels of damping, which prevents the high Q resonances that could otherwise undermine the benefits of such rigidity.

HYBRID DIAMOND x U.D. CARBON CANTILEVER DESIGN

The TESSELLATE Ti Cartridges are the first in the world to introduce a hybridised cantilever design. Since its founding in 1989, Wilson Benesch has pioneered the application of carbon fibre across many products, establishing the brand as a leader in the use of carbon fibre composites in the high-end audio industry by 2024.

To fully exploit the unique properties of carbon fibre, it is crucial for designers to understand how to work with the material. For the first time ever, a uni-directional (UD) carbon fibre sleeve has been employed in the TESSELLATE Ti Cartridge cantilever. This innovative technology marries the benefits of advanced cantilever systems with the damping advantages of UD carbon fibre, resulting in improved tracking ability through reduced resonance in the cantilever.

The UD carbon fibre adds virtually no additional mass, yet when placed in an offset asymmetrical position in the middle of the cantilever, it provides significant additional stiffness and damping. With this hybrid cantilever technology and a choice of Boron, Sapphire, and Diamond cantilevers, the TESSELLATE Ti Cartridges offer a versatile range that caters to different preferences and system requirements. Whether you prioritise accuracy, transparency, or sonic refinement, there is a cartridge with a hybrid cantilever to meet your needs.

BESPOKE

The TESSELLATE Ti Cartridges are available in three finish options.

The Matt Titanium finish is exactly as the titanium body has been ‘grown’ in the SLS machine and its surface is textured.

The Polished Silver finish is exactly as the name describes and the cartridge body has been polished by hand to create a mirrored finish.

The Polished Gold is the most premium finish available. The gold colouring is applied using vapour deposition technology after the cartridge body has been polished by hand.

CRITICAL ACCLAIM

SPECIFICATIONS

| TESSELLATE Ti-D Diamond Cartridge | ||||

| PHYSICAL | ||||

| Hybrid Cantilever | Diamond cantilever with a U.D. carbon fibre damping ring | |||

| Stylus | Micro Ridge | |||

| Stylus Tip Radius | 3x80uM | |||

| VTA | 20-degrees | |||

| Coil | Pure Iron Square Coil | |||

| Weight | 17.1g | |||

| Cartridge Body & Headshell | SLS 3D additively manufactured titanium structure, with tessellated semi-open geometry | |||

| Finish Options | Standard Matt Titanium or upgraded Polished Silver, Polished Gold (finish purely aesthetic and related no performance difference) | |||

| ELECTRICAL | ||||

| Output Voltage | 0.35mV @ 3.54CM/S | |||

| Internal Impedance | 6 Ohms | |||

| Frequency Response | 20-32,000Hz +/- 1dB | |||

| Channel Separation | Better than 35dB at 1KHz | |||

| Channel Balance | Better than 0.5dB | |||

| DYNAMIC | ||||

| Tracking ability at 315Hz at optimum tracking force | 85uM | |||

| Dynamic Compliance | 15uM/mN | |||

| SETUP INSTRUCTION | ||||

| Recommended Loading | 100-330 Ohms | |||

| Recommended Tracking Force | 1.1-1.4g | |||

| Optimum Tracking Force | 1.3g | |||

| Recommended Tonearm Mass | Medium | |||

| Optimum Working Temperature | 23 Centigrade // 73.4 Fahrenheit | |||

| Break-In Period | 30-hours | |||