THE ART OF BASS.

BASS WITHOUT DELAY.

CONTROL WITHOUT COMPROMISE.

Fidelity, Timing, and the Wilson Benesch Philosophy

Fidelity is the foundation of every Wilson Benesch design. And because timing shapes rhythm, space, and coherence, it is the measure by which fidelity is truly achieved.

The human ear is more sensitive to timing than to pitch or loudness. We can detect differences of just a few microseconds — far more precise than our ability to hear changes in frequency. Timing governs rhythm, musical flow, and the way we perceive instruments in space. As such, any transient delays in the loudspeaker — mechanical, electrical, or acoustic — are a direct loss of fidelity in the original signal provided from the source.

This principle has guided Wilson Benesch in pioneering new technologies and refining established ones to the highest level. Notable technological highlights of the current-generation Fibonacci Series loudspeaker line include:

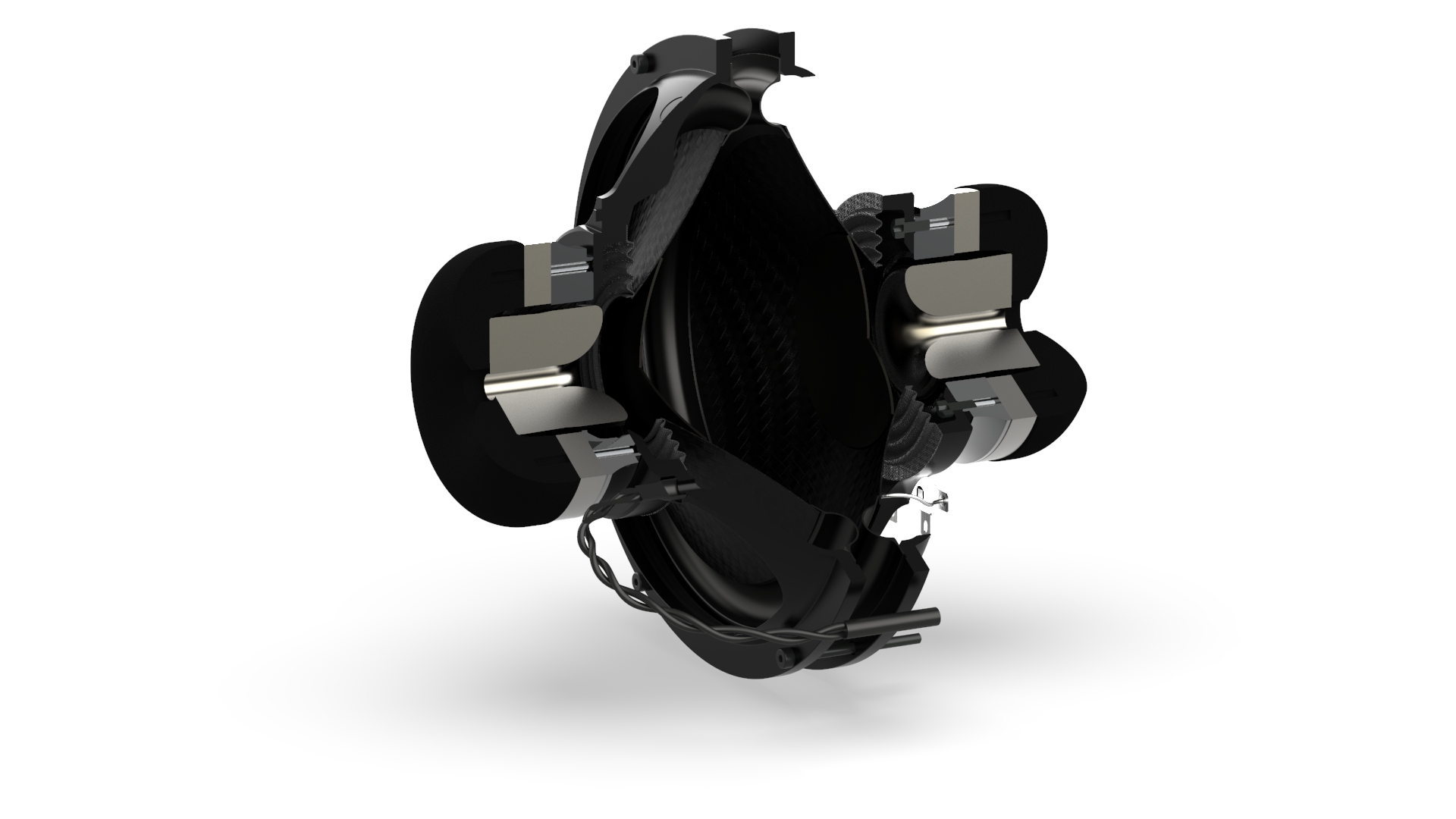

Isobaric Drive Systems — not invented by Wilson Benesch, but developed and refined through decades of research into the fastest, most coherent low-frequency reproduction. First introduced in 1999 with the Bishop loudspeaker and later perfected in the Odyssey Series, the isobaric principle remains central to the Fibonacci Series design language.

Reductive crossover design — avoiding unnecessary electrical components to minimise phase shift and preserve time coherence.

Rare-earth NdFeB magnets — Wilson Benesch was among the earliest high-end loudspeaker manufacturers to design its own drive units around these powerful magnets in the 1990s, enabling unmatched transient speed and control.

Advanced carbon composites — pioneered in audio by Wilson Benesch with the world’s first tapered carbon fibre tonearm (1992) and the curved carbon fibre A.C.T. One loudspeaker enclosure (1994). In the Fibonacci Series, this technology has evolved into new bio-based composite monocoques derived from sustainable natural fibres.

Sloping and curved loudspeaker tops — the 20-degree sloped top was first introduced with the A.C.T. One loudspeaker in 1994, at a time when rectilinear wooden enclosures dominated the industry. The sloped, curved form profoundly alters the interaction between the loudspeaker and the listening environment. Rather than reflecting sound energy directly, the complex geometry diffracts and dissipates acoustic waves across a wide surface area, preventing standing waves and reducing the enclosure’s acoustic signature. This allows the loudspeaker to disappear more stealthily within the listening space — a design philosophy perfected in the Eminence and Resolution 3zero loudspeakers, whose organically sculpted tops represent the highest expression of this principle.

Isotactic Polypropylene (IPP) — developed in collaboration with Professor Ian Ward and first commercialised by Wilson Benesch in drive unit diaphragms. IPP offers a unique balance of stiffness and damping, ensuring pistonic accuracy without the harsh breakup modes associated with harder materials.

Design Mantra

“There are no transient delays in nature.”

Every natural sound event — a plucked string, a struck drum, a voice — begins and ends instantly. A loudspeaker should do the same.

What Does “Isobaric” Mean?

Isobaric (adj.) — from the Greek iso (“equal”) and baros (“pressure/weight”) — literally means “at equal pressure.”

In loudspeaker design, an isobaric system couples two drive units so that the air between them remains at nearly constant pressure. The cones move as one, creating a low-resonance system that delivers deep, articulate bass from compact enclosures.

The Principle of Transient Speed

Large woofers cannot achieve true speed: their heavy cones accelerate and decelerate too slowly, smearing musical timing.

Parallels can be drawn with the philosophy of Colin Chapman of Lotus Engineering, who revolutionised automotive design with his pursuit of lightness. Chapman famously observed: “Adding power makes you faster on the straights. Subtracting weight makes you faster everywhere.” Just as a lighter car responds more quickly in every situation — accelerating, braking, and cornering — a lighter loudspeaker diaphragm responds more faithfully to the musical signal, preserving timing and coherence.

The Wilson Benesch Isobaric Drive System embodies this principle. Two ultra-light diaphragms, tightly coupled and powered by high-strength rare-earth motors, move as one. The dual-motor design is equivalent to Chapman’s “adding power,” while the lightweight diaphragms reflect his “subtracting weight.” Together, they deliver bass that is fast, articulate, and seamlessly integrated with the midrange — the rhythmic foundation upon which music lives.

This behaviour is clearly revealed in the step response. Whereas conventional bass drivers exhibit slow rise times, overshoot, and ringing, the isobaric system behaves with the speed and control of a small driver. In fact, the step response of the Wilson Benesch isobaric bass system is often comparable to — and in many cases faster than — the midrange. This alignment is crucial: rather than the bass lagging behind, the entire system speaks with one voice, preserving the full timing integrity of the musical performance.

Colin Champman

British engineer, inventor & founded of Lotus Cars

“Adding power makes you faster on the straights. Subtracting weight makes you faster everywhere.”

What is Step Response?

The step response shows how a loudspeaker reacts to a sudden input signal — an electrical “step” that jumps instantly from zero to a fixed level.

An ideal drive unit would move instantly to the new position, hold steady without overshoot, and return instantly when the signal stops. In practice, inertia and resonances cause delays, overshoot, or ringing.

A clean, fast step response means sharp, natural transients — the attacks and decays that make music feel alive. A slow or messy step response smears timing and blurs musical detail.

The Physics of Isobaric Loading

In a conventional loudspeaker, low-frequency extension is achieved by increasing diaphragm size and cabinet volume. A larger cone can move more air, and a larger enclosure provides the compliance required to tune it to low frequencies. But these apparent solutions carry serious compromises. A large woofer has greater moving mass, so it cannot accelerate or decelerate as quickly. Its suspension systems — the surround and spider — must be stiffer to maintain control, storing energy that blurs timing. At the same time, the cabinet required to house such a driver grows in scale, reducing stiffness and also increasing the sonic signature of the enclosure by virtue of its larger size.

The isobaric principle offers a radically different approach. By coupling two drive units face-to-face or front-to-back, the air trapped between them is held at nearly constant pressure — “isobaric” in the truest sense. The two diaphragms move as one, sharing the load while presenting the acoustic behaviour of a single driver to the outside world. The drivers are wired electrically in parallel and move in unison, ensuring perfect synchronisation of their motion. Crucially, the resonant frequency of the system is halved compared to a single driver in the same volume, meaning bass can be extended without resorting to oversized cones or enclosures.

In Wilson Benesch designs, this principle is taken further. Each diaphragm is ultra-light yet super-stiff, formed from advanced materials to maintain pistonic accuracy. Each has its own high-power rare-earth motor, ensuring absolute control and symmetry of movement.

The outcome is a system that combines the virtues of deep extension, compact enclosure volume, and extraordinary speed. Where a traditional large woofer is inevitably compromised by mass, inertia, and cabinet noise, the Wilson Benesch Isobaric Drive System achieves bass reproduction that is low in frequency yet high in fidelity — tight, articulate, and seamlessly integrated with the midrange.

Wilson Benesch and the Isobaric Principle

Wilson Benesch first implemented the Isobaric Drive System with the introduction of the Tactic 1.0 Drive Unit in the now iconic Bishop loudspeaker of 1999. The Tactic 1.0 was developed through a £250,000 R&D programme part-funded by the UK Department of Trade and Industry (DTi). This landmark project not only marked the beginning of Wilson Benesch’s in-house drive unit development but also laid the foundation for decades of continuous innovation in drive unit design and isobaric bass systems.

Why Isobaric Is Rare

Despite its many advantages, the isobaric configuration remains uncommon in loudspeaker design. Historically, designers avoided it because pairing two drive units to move the same air volume reduces sensitivity by around 3 dB, demanding more amplifier power.

Over the past three decades, however, amplifier technology has advanced dramatically. High-power solid-state designs that were once rare and costly are now commonplace, with many integrated amplifiers comfortably delivering hundreds of watts into demanding loads. Modern amplifiers also provide far higher current delivery and damping factors, giving them the control necessary to exploit the precision of an isobaric system. As a result, the modest sensitivity loss that once discouraged designers is no longer a significant limitation in the context of contemporary high-end audio.

Equally important, Wilson Benesch loudspeakers are not inherently difficult loads. With sensitivities typically in the 89–90 dB range and nominal impedance of 6 Ω, dipping towards 4 Ω, they present a clean and predictable electrical profile. Thanks to reductive crossover design, impedance phase angles are well controlled, avoiding the severe swings that make some loudspeakers truly amplifier-challenging. While they reward amplifiers with good current delivery and control, they remain far from the “difficult load” category often associated with complex, inefficient designs.

Wilson Benesch also does not voice or optimise its loudspeakers around any single type of amplification. The company’s founders use both valve amplifiers and solid-state designs, at home and within the listening and development facilities. This broad approach ensures neutrality and versatility, allowing WB loudspeakers to partner successfully with the widest possible range of electronics. Amplifiers from companies such as Ypsilon, Trilogy, WestminsterLab, CH Precision, NuPrime, and Jolida are all in regular use, reflecting a philosophy of inclusivity rather than dogma.

The greater challenges lie not in performance but in engineering. An isobaric system requires two perfectly matched drive units, dual motor assemblies, and either a precision-engineered coupling chamber in a magnet-to-cone design, or a mounting collar in a clamshell design such as that used by Wilson Benesch. The structure is more demanding, with additional baskets, magnets, and cabinet reinforcement adding weight and complexity. All of this inevitably adds significant cost. Most critically, both drivers must behave identically, so high-quality drive units that are built with absolute precision are essential.

For these reasons, most manufacturers avoid the isobaric principle. Wilson Benesch, however, has embraced it as part of a philosophy of engineering without compromise. By designing and manufacturing its own drive units, and by applying advanced materials and precision engineering, Wilson Benesch overcomes these challenges — unlocking the full potential of the isobaric system. The reward is bass reproduction that is deeper, faster, and more articulate than any conventional large-woofer design.

Applications Across the Fibonacci Series

With the sole exception of the Horizon — the entry-level floorstanding model in the collection — every loudspeaker in the Fibonacci Series employs an Isobaric Drive System for bass reproduction. From the compact Discovery 3zero to the flagship Eminence, the isobaric principle is a defining technology of the range, ensuring fast, articulate, and perfectly integrated low-frequency performance across the series.

The Ultimate Foundation

The Isobaric Drive System is more than a woofer topology: it embodies Wilson Benesch’s philosophy of engineering without compromise. By harnessing the laws of physics, pioneering advanced materials, and placing timing at the heart of fidelity, Wilson Benesch achieves bass reproduction that is powerful, articulate, and perfectly integrated — the true foundation of natural sound.

Equally, the Isobaric Drive System is not an isolated technology. It forms part of a holistic design approach that extends through every element of a Wilson Benesch loudspeaker: the pistonic accuracy of the Tactic 3.0 midrange, the refinement of the Fibonacci tweeter, the reductive crossover topology, and the advanced composite enclosures. Each technology is developed in-house, each material and process carefully chosen and controlled.

It is this integration — the ability to design and manufacture every critical component — that allows Wilson Benesch to create loudspeakers that are greater than the sum of their parts. True high-end loudspeaker design cannot be achieved by combining off-the-shelf drivers in a conventional cabinet; it demands complete mastery of the entire system. Only then can something truly unique be realised.