IF NATURE GREW A TONEARM, IT WOULD PROBABLY LOOK LIKE THIS

The GRAVITON® Ti Tonearm is the culmination of more than three decades of Wilson Benesch research in composites, additive manufacturing, and precision engineering. It is the first high-end tonearm in the world to unite a hand-laid graphene-reinforced carbon fibre armtube with 3D-printed titanium structures—an innovation born from collaborations with leading UK and European research institutions.

Engineered for the most discerning audiophiles and collectors, the GRAVITON® Ti delivers unprecedented neutrality, control, and resolution in vinyl replay. Every element of its design has been created to master resonance, optimise energy flow, and preserve the delicate musical signal traced from the record groove. In doing so, it sets a new benchmark for analogue sound reproduction, redefining what is possible from a tonearm in the service of the vinyl record.

Redefining a Tonearm

A tonearm is far more than a simple mechanical lever—it is the critical link between the stylus and the musical signal hidden in the groove. Yet for decades, tonearm design has followed conventions that compromise performance, relying on multi-part assemblies and bolted joints that introduce reflection points, resonances, and distortion.

The GRAVITON® Ti breaks from this history. Every decision, from materials to geometry, has been rethought to create a tonearm that operates as a seamless, unified structure. It is not an iteration—it is a redefinition of the form, engineered to preserve the signal with absolute fidelity.

Hybrid Engineering: Carbon Fibre & Titanium

The GRAVITON® Ti Tonearm embodies a unique fusion of two of the most advanced structural materials available: hand-laid carbon fibre composites and additively manufactured titanium. This hybrid design draws upon Wilson Benesch’s 35 years of leadership in composite engineering, combined with a world-first application of Selective Laser Sintering (SLS) titanium structures in tonearm design.

At its core lies the carbon fibre armwand, laid by hand in a quadruple helix within Wilson Benesch’s proprietary Vacuum Resin Transfer Moulding (VRTM) system. This method ensures the highest consistency and optimised performance, free from the limitations of generic pre-preg layups or repurposed tubes.

This is complemented by titanium counterbalance structures grown, not machined, using state-of-the-art additive manufacturing. Developed in collaboration with the Advanced Manufacturing Research Centre (AMRC) at The University of Sheffield and metal AM specialists Renishaw PLC, these titanium forms follow the helix of the carbon fibre tube with a seamless logic dictated entirely by function. Hollow, tessellated, and solid sections are selectively employed, minimising mass while maximising stiffness and damping.

The result is a tonearm of exceptional structural harmony: carbon fibre and titanium working as one, combining the best of lightweight composite behaviour with the precision, adaptability, and geometrical sophistication only possible through additive manufacturing. This hybrid begins with the armtube itself, a quadruple helix carbon fibre structure unlike anything else in audio.

Quadruple Helix Carbon Fibre Armtube

The GRAVITON® Ti Tonearm introduces a one-of-a-kind quadruple helix carbon fibre layup, hand-laid by Wilson Benesch’s skilled composite engineers at its factory in Sheffield. Unlike off-the-shelf carbon tubes repurposed for audio, this armtube was designed from first principles to meet the exacting demands of ultra high fidelity vinyl replay.

Each carbon fibre ply is cut by hand and meticulously laid in a quadruple helical pattern, wrapping around the armtube in four distinct spirals. This complex orientation distributes stiffness and damping anisotropically, tailoring the structural behaviour of the armtube along multiple axes.

To achieve this, Wilson Benesch employs its in-house Vacuum Resin Transfer Moulding (VRTM) system—a process far superior to pre-preg layups supplied by OEM composites manufacturers. VRTM ensures complete resin infusion, seamless fibre consolidation, and the highest possible structural integrity. The result is a perfectly moulded armtube that achieves:

Maximum rigidity exactly where it is needed most.

Optimised distribution of mass, aligned to functional requirements.

Zero material redundancy, ensuring every fibre contributes to performance.

Unlike conventional tonearms that rely on bolt-on headshells or mechanically fastened joints, the GRAVITON® Ti features a seamless one-piece construction. The carbon fibre headshell and armtube are moulded as a single continuous structure, eliminating reflective junctions that disrupt energy flow. This uninterrupted form ensures vibrational energy is dissipated smoothly, not reflected back toward the stylus.

The result is a tonearm of remarkable stiffness, resonance control, and structural integrity—delivering an unprecedentedly pure pathway for the retrieval of musical detail from the vinyl groove.

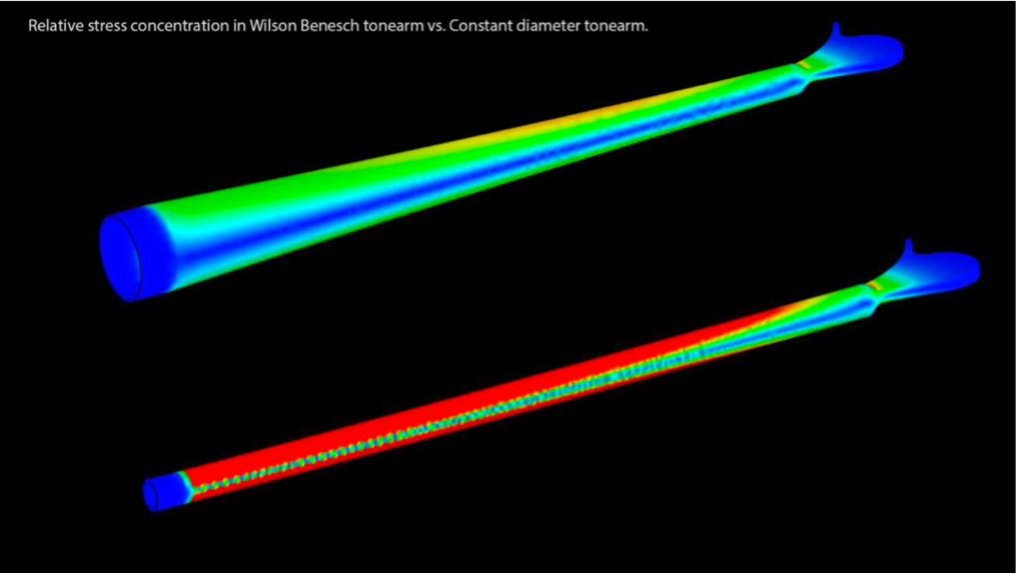

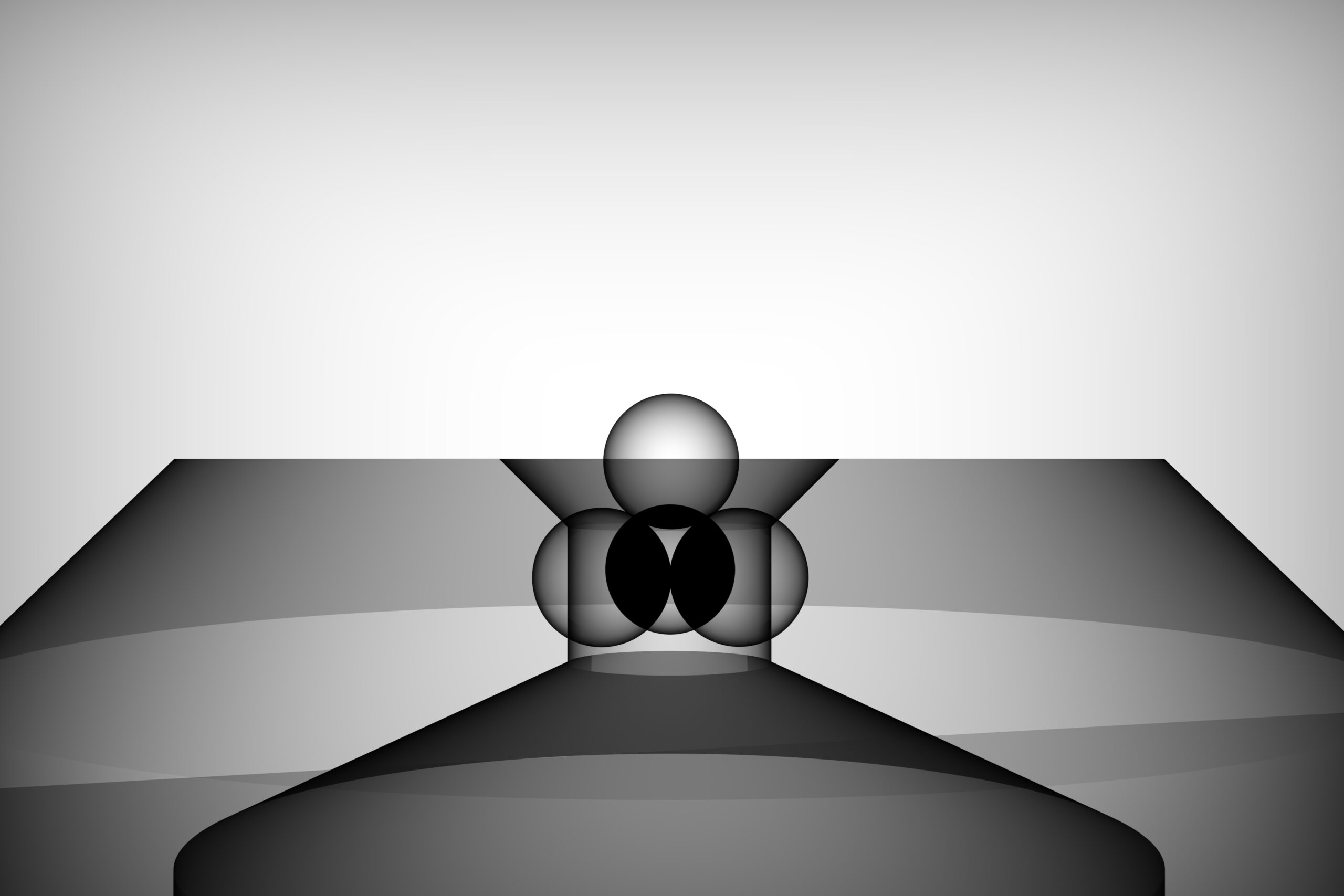

This is the heading

Finite Element Analysis of Wilson Benesch Hyperbolic Armtube Geometry: FEA Analysis highlights the superior stress distribution of the Wilson Benesch hyperbolic carbon fibre armtube (top) compared with a standard constant-diameter tube (bottom). The hyperbolic geometry reduces stress concentrations, increasing rigidity and resonance control for high-fidelity vinyl playback.

Additive Manufacturing in Titanium (SLS)

The GRAVITON® Ti Tonearm is one of the first tonearms in the world to harness Selective Laser Sintering (SLS) of titanium—a process that has redefined what is mechanically possible in analogue audio design. Unlike conventional machining, which subtracts material to form simple shapes, SLS grows titanium components layer by layer from powder, allowing the creation of highly complex geometries with zero material waste.

This freedom of form enables organic, topology-optimised structures that mirror nature’s most efficient load-bearing designs. The internal lattices of trabecular bone or the lightweight stiffness of bird beaks provided direct inspiration for the titanium counterbalance of the GRAVITON® Ti. Just as nature distributes mass only where it is structurally effective, SLS allows titanium to be placed precisely along load paths—creating hollow sections, tessellated lattices, and dense anchor points in a single continuous form.

The advantages for high-end audio are profound:

Weight Reduction without Compromise – hollowing and lattice structures eliminate redundant mass while retaining exceptional rigidity.

Strength & Stability – titanium’s high specific stiffness ensures the tonearm remains structurally inert even under dynamic tracking conditions.

Resonance Management – internal lattices and powder-filled cavities dissipate vibrational energy, preventing resonant “ringing” common in aluminium or steel.

Through this marriage of biomimicry and Fourth Generation Manufacturing, Wilson Benesch has created titanium structures impossible to realise through machining. Every curve, cavity, and lattice within the GRAVITON® Ti Tonearm exists purely for function—optimised to manage resonance, control energy flow, and deliver the ultimate resolution from vinyl replay.

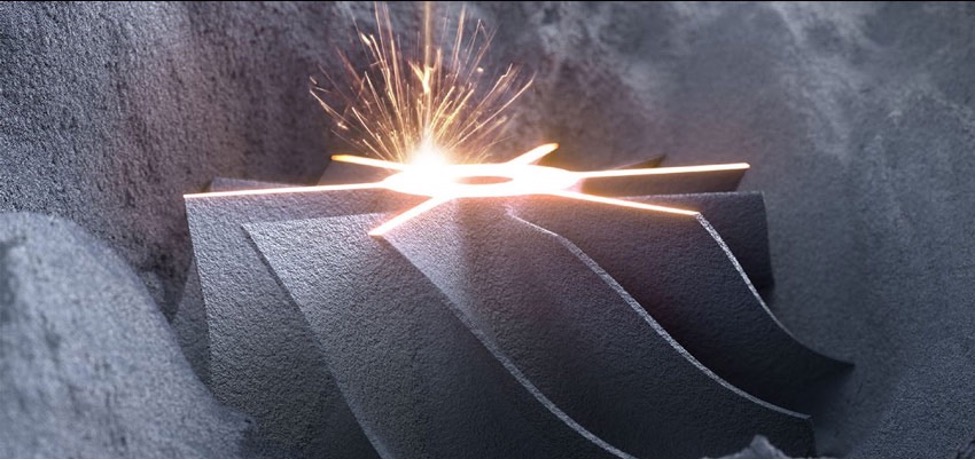

Selective Laser Sintering of Titanium for GRAVITON® Ti Tonearm

Selective Laser Sintering (SLS) in action — Titanium powder is fused layer by layer with a high-powered laser, enabling the creation of complex, organic geometries impossible to achieve with traditional machining. This process forms the titanium counterbalance structures of the GRAVITON® Ti Tonearm.

Continuity & Energy Management

From the very tip of the headshell to the rear counterbalance, the GRAVITON® Ti Tonearm has been engineered as a continuous energy pathway, eliminating the reflective junctions that compromise conventional tonearms.

The headshell is the first and most critical example. In traditional designs with bolt-on or detachable headshells, vibrational energy generated at the cartridge is reflected at the mechanical junction, feeding back into the stylus and colouring the signal. By contrast, the GRAVITON® Ti integrates the headshell seamlessly into the carbon fibre armtube, creating a direct, unbroken flow of energy from cartridge body into the tonearm tube.

This principle of continuity is carried through to the rear of the arm. In the final third of the tonearm, the additively manufactured titanium counterbalance structures interface directly with the carbon fibre tube. Here, Wilson Benesch engineers designed the titanium geometries to follow the helical pathways of the carbon fibre layup. This results in a large, precisely matched surface-area interface between the two materials, allowing vibrational energy to move smoothly from carbon into titanium without abrupt reflection points.

By mirroring the helix of the carbon fibre in titanium, the counterbalance becomes not just a structural necessity, but an active participant in the energy management of the system. Vibrations are absorbed and dissipated progressively along this path, ensuring that no single junction behaves like a reflective barrier.

The result is a tonearm that maintains continuity of energy flow across its entire length. Where conventional arms suffer from reflective breaks at their junctions, the GRAVITON® Ti achieves a seamless mechanical silence, preserving every nuance embedded in the vinyl groove.

Quadruple Helix Carbon Fibre & Titanium Counterbalance:

The GRAVITON® Ti Tonearm’s carbon fibre armtube is hand-laid in a quadruple helix pattern, illustrated here by the purple spiral. The titanium counterbalance structure at the rear is grown via additive manufacturing to follow the same helical geometry, ensuring seamless energy transfer and structural continuity.

Kinematic Bearing

At the heart of the GRAVITON® Ti Tonearm lies an advanced zirconium-based hybrid kinematic bearing system, coupled with precision-engineered subsystems and digitally actuated adjustment mechanisms. This architecture delivers ultra-low friction motion, optimised Hertzian contact mechanics, and nanometre-level setup accuracy—an achievement unmatched in high-end tonearm design.

Zirconium Hybrid Kinematic Bearing

Building on the pioneering kinematic bearing first introduced in the A.C.T. One Tonearm, the GRAVITON® Ti advances the concept with zirconium elements. These balls, polished to extreme tolerances, provide:

- Ultra-low friction – negligible rolling resistance ensures unhindered stylus motion.

- Superior energy transfer – microscopic Hertzian contact zones channel vibrational energy with maximum efficiency.

- Stiction-free motion – a three-ball hybrid configuration (two zirconium, one damping-enhanced conductive ball) guarantees absolute stability, grounding, and energy management.

This hybrid approach unites the precision of kinematic geometry with enhanced damping and conductivity, creating a bearing system of extraordinary sensitivity, resolution, and resonance control.

Technical Insight: Hertzian Mechanics in the GRAVITON® Ti Bearing

Where conventional unipivot bearings rely on a single sharp point—often trading stability for low friction—and gimbal bearings use multiple ball-race assemblies that increase stiction and energy losses, the GRAVITON® Ti’s kinematic bearing redefines the standard.

By using three 1mm balls to establish infinitesimal, perfectly defined contact points, Hertzian mechanics are exploited to their fullest:

- Defined geometry fixes the pivot in an exact, unchanging position.

- Stiction-free movement allows the stylus to track groove modulations with absolute fidelity.

- Energy path control funnels vibrational energy away from the stylus and into defined dissipation pathways.

The result is a bearing that combines the frictionless agility of a unipivot with the stability of a gimbal—while surpassing both. Every nuance within the vinyl groove is preserved, delivering the ultimate in audiophile-grade vinyl replay.

GRAVITON® Ti Tonearm – Kinematic Bearing X-Ray Render

GRAVITON® Ti Tonearm – Kinematic Bearing: An X-ray render of the GRAVITON® Ti Tonearm kinematic bearing, showing three ball bearings supporting a fourth centred above them, illustrating the ultra-precise Kinematic Bearing design.

Perfect Precision Everytime: Piezo-Drive VTA Adjustment

In the development of the GMT® Collection, Wilson Benesch has consistently drawn upon advanced technologies from beyond the world of audio to build the ultimate analogue replay system. In the GMT® One System Turntable, a pneumatic isolation system, adapted from electron microscopy, isolates the entire turntable from resonant energy. Extending this philosophy, the GRAVITON® Ti Tonearm integrates another breakthrough from a field of extreme precision: piezo-actuation, the same technology used in telescopes to track distant stars with nanometre accuracy.

In high-end audio, this translates into a revolutionary approach to Vertical Tracking Angle (VTA) adjustment. Where conventional tonearms rely on a simple M3-threaded adjuster—with coarse tolerances, inherent backlash, and mechanical play—the GRAVITON® Ti’s piezo-driven system delivers adjustments in increments as fine as 1 nanometre. To put this into perspective: a human hair measures around 80,000–100,000 nanometres across.

This radical increase in resolution ensures that stylus rake angle (SRA) can be dialled in with perfect, repeatable accuracy. For the listener, this means:

Optimal tracking of the vinyl groove, maximising information retrieval from every record.

Reduced record wear, since the stylus maintains an ideal alignment with the groove walls.

Repeatable setup accuracy, supported by the GMT® Control App GUI, which displays VTA position numerically so users can return to memorised settings with ease.

Technical Insight: From the Stars to the Groove

In telescopy, piezo devices are deployed to track the motion of distant stars with unrivalled precision—in these systems even the smallest mechanical inaccuracy would result in catastrophic error over astronomical distances. In a similar way, the GRAVITON® Ti Tonearm harnesses piezo actuation to eliminate the inaccuracies of threaded systems, applying this extreme precision to the world of vinyl replay. What astronomers need to navigate the stars, audiophiles now have to unlock the last word in groove resolution.

**Availability: The Piezo-Driven VTA Adjustment system is available exclusively when the GRAVITON® Ti Tonearm is mounted on Wilson Benesch GMT® One or Prime Meridian System Turntables.

EcoGrip® High Precision Chuck

At the foundation of the GRAVITON® Ti Tonearm’s bearing assembly lies the EcoGrip® hydraulic chuck—a clamping system borrowed from industrial machining and re-engineered for high-end audio. Where conventional tonearms often rely on screw-based or collet-style clamps that introduce uneven stresses, the EcoGrip® ensures a perfect, stress-free union between the armtube and bearing hub.

Key advantages:

Absolute conformity – Hydraulic actuation expands uniformly, wrapping the chuck evenly around the shaft and eliminating point loading.

Friction-free adjustment – A graphite-lubricated interface guarantees smooth, repeatable travel during setup.

Unaltered geometry – Locking the chuck introduces no deformation, ensuring the bearing pivot remains in perfect alignment.

The result is a foundation of manufacturing-grade precision. By removing distortion and stress at this critical junction, the EcoGrip® enables the nanometric accuracy of the GRAVITON® Ti’s zirconium hybrid kinematic bearing and piezo-driven VTA adjustment to perform at their full potential—preserving signal integrity and unlocking the most faithful vinyl replay.

STAGE One: Pure Signal Architecture

The STAGE One system forms the final link in the GRAVITON® Ti Tonearm’s mechanical and electrical architecture, ensuring that the fragile cartridge signal is preserved with absolute neutrality from the moment it leaves the armwand.

At the heart of this system is the “over-arm” cable exit, where the tonearm wire is routed vertically, directly above the pivot point. In conventional tonearms, the cable exits behind the pivot in a loop, where its memory and torsional resistance act like a spring, constantly disturbing the equilibrium of the bearing. The GRAVITON® Ti eliminates this weakness: with the cable emerging directly above the pivot, no torsional forces are transmitted to the bearing assembly. The result is a tonearm that remains in a state of pure mechanical neutrality, free from reactive stresses that could disrupt stylus tracking.

Equally critical is the signal shielding architecture. From the carbon fibre armtube, the tonearm wire transitions into a compact copper-shielded STAGE One enclosure, with less than one inch of unshielded cable exposed. This creates an EMI-resistant chamber that protects the microvolt-level signal—often as low as 0.2–0.5 millivolts—from environmental interference at the most vulnerable point in the signal path.

Because the phono preamplifier must amplify this signal by more than a factor of 1,000 to reach line level, even the smallest distortion, interference, or mechanical stress introduced here would be amplified exponentially. The STAGE One’s design eliminates these risks by combining mechanical decoupling, torsion-free routing, and robust EMI shielding.

The outcome is a signal path of unmatched purity—mechanically neutral, electrically silent, and optimised for ultra-low-noise performance—ensuring the vinyl groove is reproduced with the highest possible fidelity.

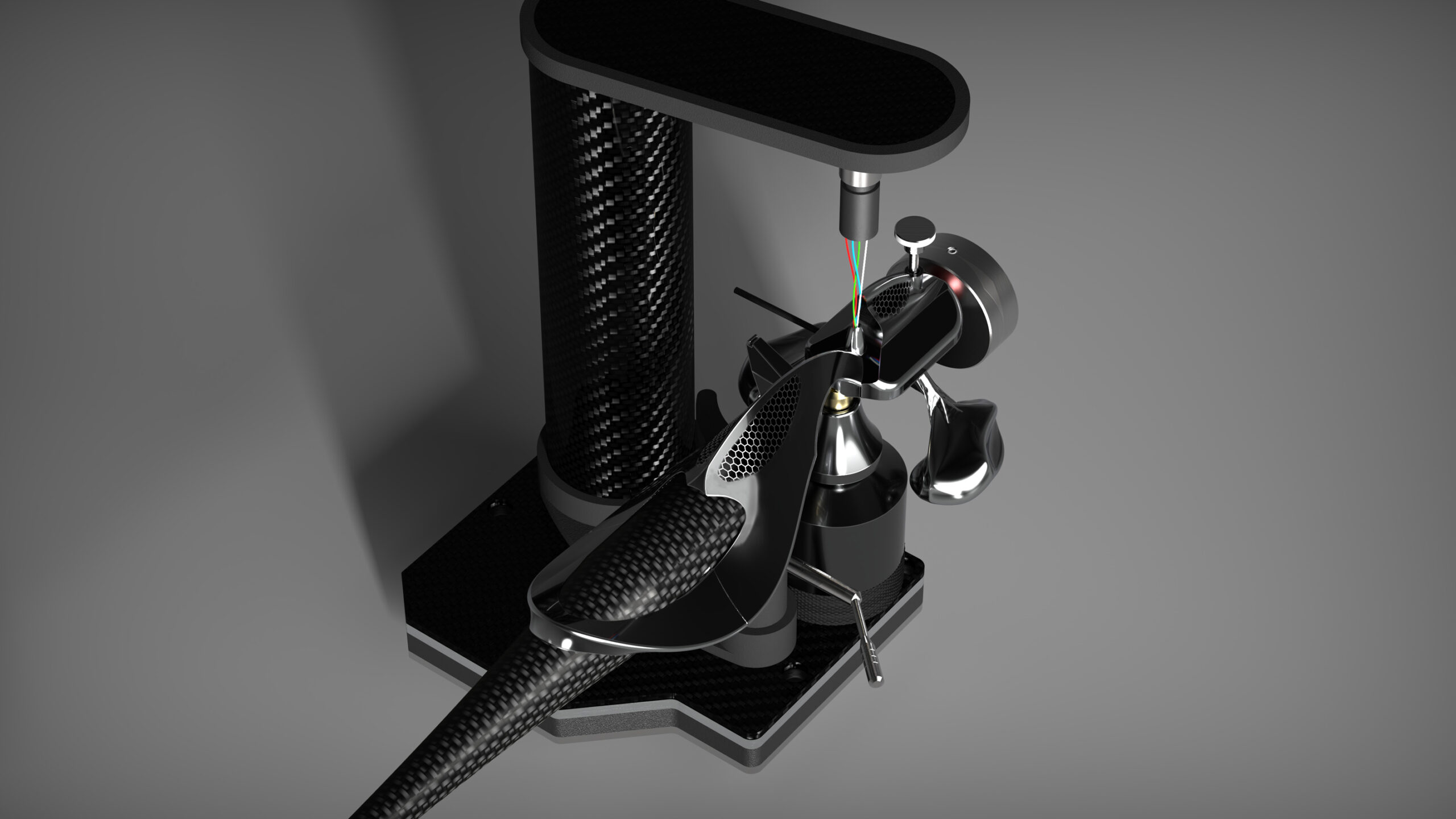

This is the heading

GRAVITON Ti Tonearm and STAGE One Platform: A Close-up view of the GRAVITON Ti Tonearm mounted under the STAGE One in the version of the tonearm made for third party turntables

International Engineering Collaboration & Manufacturing Excellence

The GMT® Collection and its GRAVITON® Ti Tonearm are the result of a rare union between world-leading research institutions and Wilson Benesch’s in-house manufacturing expertise.

In close collaboration with the Advanced Manufacturing Research Centre (AMRC) at the University of Sheffield and Renishaw PLC, Wilson Benesch translated radical design concepts into reality using selective laser sintering (SLS) in titanium. This pioneering work was strengthened further by academic partnerships with the FEMTO Institute in France, drawing upon decades of research into vibration control and energy transfer. The wider GMT® Consortium also benefitted from the expertise of Professor Carl Broomfield, Dr Neil Broomfield, Professor Jon Travis, Professor Graham Cockerham and Dr Faris Al-Naemi, each making crucial contributions that enabled the delivery of the GMT® One System Turntable.

Equally vital is Wilson Benesch’s commitment to self-reliance and vertical integration. Every carbon fibre component—most notably the hand-laid quadruple-helix armtube and moulded headshell—is designed, manufactured, and finished entirely in-house at the company’s Sheffield facility. All metal components are milled and turned within the Wilson Benesch factory. This ensures absolute fidelity to the design intent, free from compromise and untouched by off-the-shelf OEM solutions.

The GRAVITON® Ti thus stands as a product of both cutting-edge international research and Sheffield’s enduring tradition of precision engineering, establishing a new benchmark in high-end audio manufacturing.

Engineering Acoustic Excellence

Every element of the GRAVITON® Ti Tonearm has been conceived to solve a specific engineering challenge—yet its true achievement is revealed in the listening experience. By combining advanced carbon fibre composites, additively manufactured titanium, hybrid kinematic bearings, piezo-actuated VTA, and EcoGrip® precision clamping, the GRAVITON® Ti delivers performance that is not just measurable, but audible.

Sonic advantages include:

Lower distortion – Energy pathways are precisely managed, preventing resonances from feeding back into the cartridge and ensuring that only the information in the groove is heard.

Greater resolution – Nanometre-accurate setup and ultra-low friction bearings allow the stylus to follow the most delicate groove modulations, retrieving micro-detail with unprecedented clarity.

Neutrality and purity of signal – Free from coloration introduced by reflective joints, metallic ringing, or mechanical backlash, the GRAVITON® Ti presents music with absolute tonal honesty.

Vinyl longevity – Perfectly repeatable geometry, stable VTA, and ultra-low-friction tracking reduce record wear, extending the lifespan of treasured vinyl collections.

In practice, this translates into a listening experience where the medium disappears, and the recording is laid bare in its truest form—music replayed with the same intent and intensity captured in the studio.

Leading The New Era of Analogue

The GRAVITON® Ti Tonearm represents a decisive step forward in analogue replay—melding world-first applications of additive manufacturing in titanium, a quadruple-helix carbon fibre armtube, and piezo-driven nanometre precision adjustment. No other tonearm brings together such a union of advanced materials science, biomimicry, and collaborative research with some of the world’s leading institutions.

By eliminating traditional compromises—threaded adjusters, bolt-on headshells, and off-the-shelf components—Wilson Benesch has redefined what a high-end tonearm can achieve. The GRAVITON® Ti stands not only as the new reference in tonearm design, but also as a vision of the future, where precision engineering and sonic artistry converge to unlock the deepest truths within the vinyl record.

We invite you to learn more about the GRAVITON® Ti by visiting the dedicated product page and downloading the full white paper, which details the technologies and research underpinning this landmark design.