AT THE ORIGIN OF EVERY NOTE

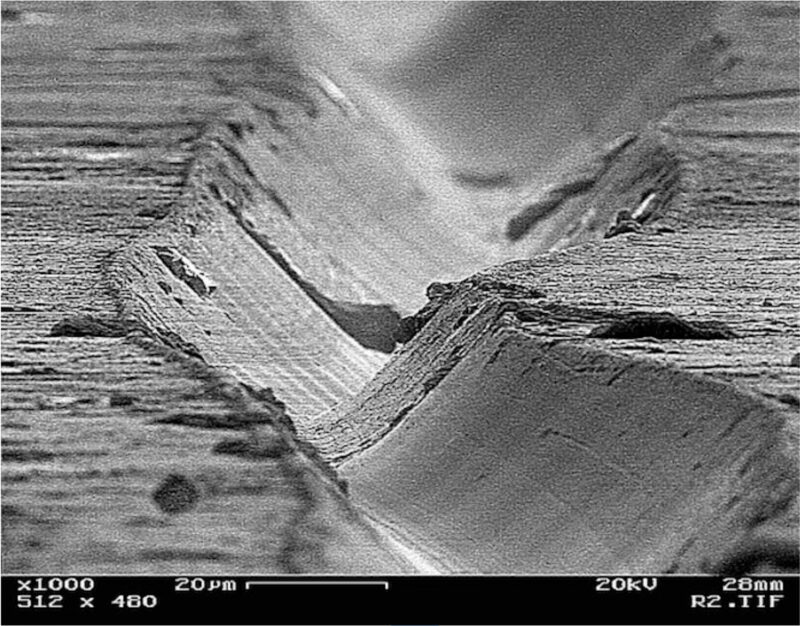

The cartridge is the starting point of all sound reproduction in a vinyl playback system. As the stylus traces the intricate modulations within the record groove — illustrated in microscopic detail below — its motion is converted into an electrical signal by the cartridge’s generator. This delicate signal is then amplified approximately 1,000 times per channel by the phono preamplifier, before undergoing a second stage of amplification in the power amplifier to drive the loudspeakers.

Given this enormous degree of amplification, even the most minute imperfections—whether due to resonance, reflection, or structural distortion within the cartridge—are amplified many thousands of times before reaching the listener. To address these challenges, a precisely engineered cartridge, designed with optimal geometry and materials, can retrieve the finest musical details with remarkable fidelity, forming the very foundation of true high-end analogue reproduction.

Historical Context: Wilson Benesch’s Engineering & Materials Design Legacy

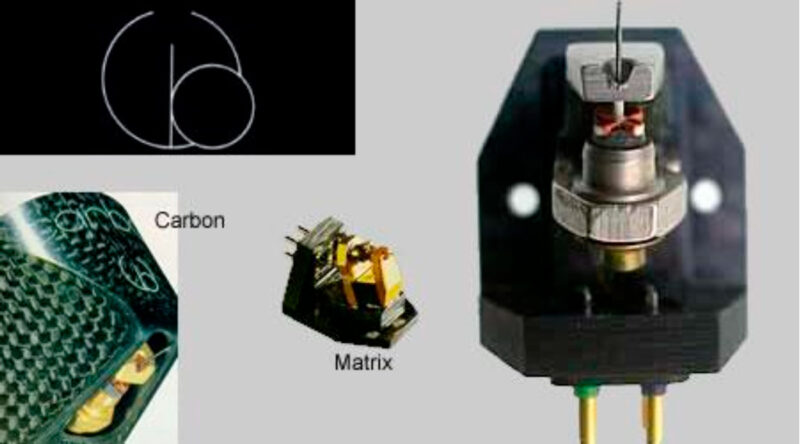

In 1992, Wilson Benesch introduced the world’s first carbon fibre body design to analogue cartridges. This pioneering development marked a significant departure from conventional cartridge construction, leveraging the exceptional stiffness-to-weight ratio and inherent damping characteristics of carbon fibre. It was the beginning of a new materials science-led approach to analogue design that would define the company’s engineering ethos. Collaborating with Benz Micro, Wilson Benesch developed a series of cartridges – CARBON, ANALOGUE, and PLY: each explored how geometry and composite construction directly

influenced sonic performance:

• The CARBON, with its flat-sided carbon shell, reflected vibrational energy back into the generator, introducing audible colouration.

• The ANALOGUE cartridge adopted a curved shell geometry, which reduced these reflections and delivered improved resolution.

• The PLY featured an entirely open-body design, virtually eliminating shell reflections but introducing a different acoustic signature due to its exposed structure.

These early explorations demonstrated that the geometry, material selection, and interface design of the cartridge body directly govern its resonance behaviour and, by extension, its musical performance. This research laid the essential foundation for the TESSELLATE Ti Cartridge – a design that reimagines these core principles through the lens of modern additive manufacturing.

The Next Step: Titanium and Additive Manufacturing

The TESSELLATE Ti Cartridge represents a natural progression from the foundational principles established in Wilson Benesch’s early carbon fibre designs. It preserves two critical design elements: a semi-open architecture, which eliminates reflective flat surfaces and allows vibrational energy to dissipate, and the U-section geometry, which achieves high specific stiffness using minimal material. In the image below, on the left the TESSELLATE Ti when viewed in side profile showing clearly its tessellated semi-open structure. In the middle a view from the back showing clearly the U-section geometry. And on the left the cartridge in an auxiliary view showing the complex curvature of the headshell.

The U-section geometry achieves the stiffness of an 18 mm solid structure with less than 30% of the mass, thanks to its U-section and honeycomb tessellations. The result is a semi-open structure with the highest specific stiffness ever seen in any cartridge, including the carbon fibre designs that preceded it.

However, the TESSELLATE Ti goes far beyond its predecessors through the use of additive manufacturing, specifically a process known as Selective Laser Sintering (SLS).

SLS is an advanced form of metal 3D printing. Unlike conventional machining, which removes material from a solid billet, SLS builds the component layer by layer from an ultra-fine titanium powder. In the TESSELLATE Ti, multiple high-powered lasers fuse titanium particles in an inert gas atmosphere, creating a seamless structure.

This technique enables design freedom that was entirely unachievable in the 1990s. The TESSELLATE Ti’s body incorporates a number of physical features that are essential to its structural and acoustic performance:

• Tessellated lattice sidewalls, clearly visible in the cartridge’s flanks, dramatically reduce mass while significantly increasing stiffness. These lattices act as energy diffusers, eliminating flat reflective surfaces that would otherwise amplify resonances.

• The U-section geometry, seen clearly in the rear view, provides the body with exceptional rigidity while minimising material use, delivering a structure that is both incredibly stiff and exceptionally lightweight.

• A complex asymmetric curvature in the headshell region, which avoids symmetry-based standing waves and promotes chaotic dispersion of vibrational energy. This contributes to internal damping and suppresses resonance peaks. This structural optimisation results in a cartridge body with:

• No material redundancy, with every gram serving a structural or acoustic purpose.

• An extraordinary stiffness-to-weight ratio, enabling cleaner energy transmission.

• Internal damping, achieved through deliberate use of curved surfaces and tessellated geometries that absorb and diffuse resonance Figure 6 illustrates these features in detail. The side profile highlights the tessellated lattice pattern, the rear view shows the U-section body form, and the auxiliary view captures the

intricate curvature of the headshell — geometries made possible only through advanced SLS titanium manufacturing.

Interference Fit: Unifying Cartridge and Tonearm

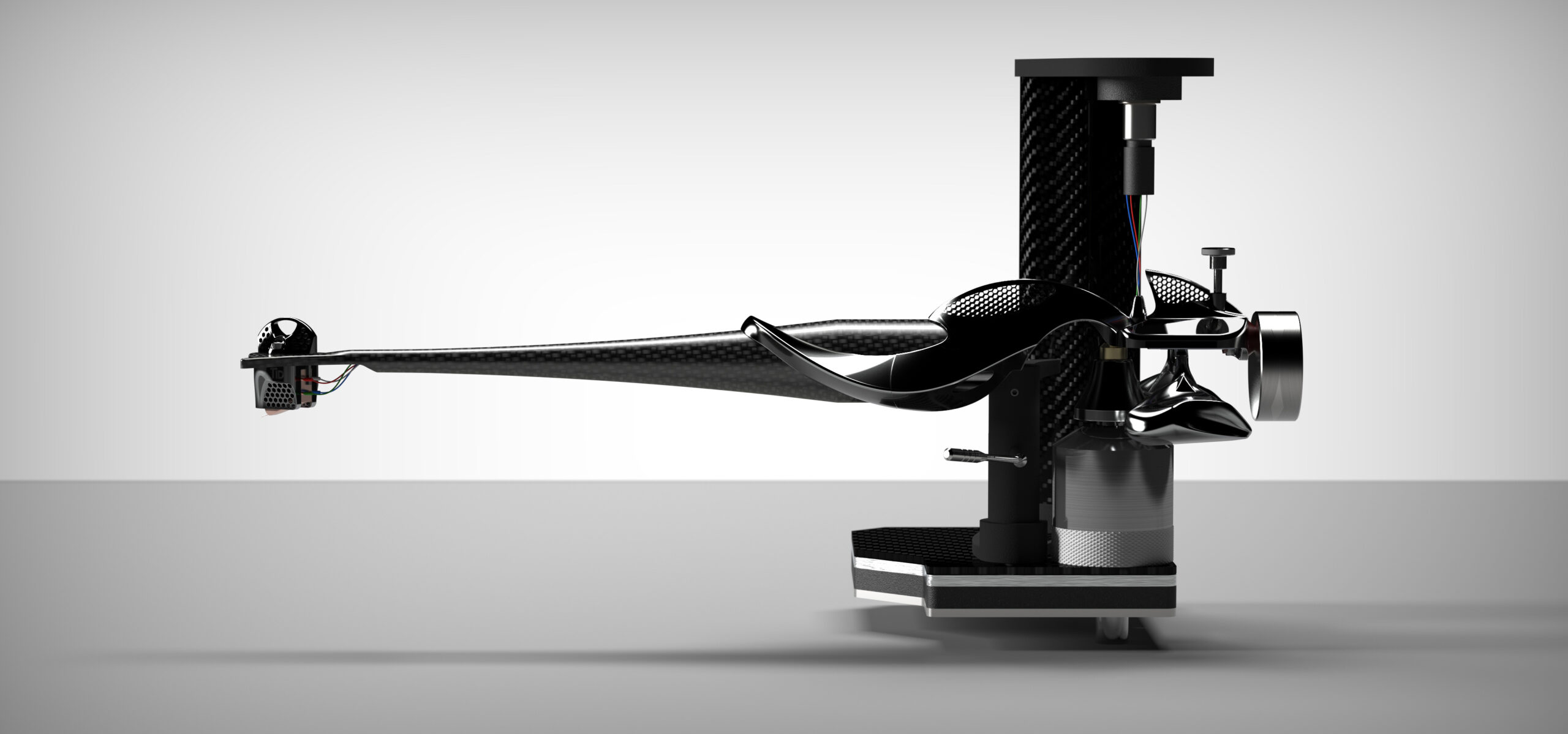

Seen below, the TESSELLATE Ti Cartridge fitted to the end of the Wilson Benesch GRAVITON Ti Tonearm. A unified design of cartridge and tonearm, showing the FIN fitted above the cartridge with the U.D. carbon fibre headshell of the tonearm between.

The advanced geometry of the TESSELLATE Ti Cartridge not only optimises stiffness and resonance control within the cartridge body itself but also forms a critical interface with the tonearm. For the cartridge to perform at its absolute best, it must be coupled to the headshell in a way that is both mechanically rigid and acoustically damped.

This is the heading

In conventional vinyl systems, cartridges are bolted to seemingly flat headshell surfaces. In reality, these surfaces are never perfectly flat, and contact is made at only a few microscopic points. This results in an unpredictable, non-linear energy transfer path that allows resonant energy to reflect, interfere, and feed back into the cartridge generator. Furthermore, such rigid metal-to-metal contact provides no inherent damping, compounding the problem.

The TESSELLATE Ti Cartridge eliminates these limitations through an interference fit. Its tessellated honeycomb interface, which can be observed in Figure 8, is additively manufactured directly into the titanium body and is designed to work in concert with a thin layer of viscoelastic adhesive.

This is the heading

When mounted, the adhesive is applied as a uniform film to the headshell. As the cartridge is bolted into position, the adhesive flows into the hexagonal lattice, forming precisely shaped polymer cushions. This achieves three key effects:

• Maximised surface area: The adhesive fills every cavity in the tessellated pattern, creating a broad, continuous contact surface rather than three microscopic points.

• Energy damping at source: The viscoelastic material converts vibrational energy into heat at the interface, preventing it from reaching the tonearm or reflecting back into the cartridge.

• Structural unification: Once cured and torqued, the cartridge and headshell behave as a single, integrated structure, eliminating micro-movement and maintaining geometric precision.

This bonded interface is unlike any traditional mounting method. It is not simply bolted, nor merely damped – it is both: rigidly fixed and acoustically controlled. The result is an energy transfer path that is predictable, linear, and highly damped, allowing the generator to work from a mechanically stable reference.

Moreover, this approach directly suppresses sympathetic resonances within the tonearm itself. Even the stiffest tonearms can exhibit structural excitation above 6 kHz, which, if undamped, re-enters the signal path with time delays. By neutralising this energy at the cartridge–headshell junction, the TESSELLATE Ti prevents it from colouring playback, leading to tighter transients, improved micro-dynamics, and greater clarity across the frequency spectrum.

The interference fit is therefore not merely a mounting refinement; it is a critical extension of the cartridge’s engineering. By integrating the titanium cartridge body and carbon fibre headshell into a single mechanically bonded system, Wilson Benesch has effectively unified the first link in the analogue replay chain.

The FIN: Extending Engineering Beyond the Cartridge

Traditionally, cartridges are supplied with two Allen bolts and washers for headshell mounting. This simple approach, while adequate for conventional systems, fails to address the mechanical and acoustic challenges inherent at this critical interface.

By contrast, the FIN represents a fundamental departure from convention. It embodies the extensive R&D behind the Wilson Benesch GMT System, where the cartridge, tonearm, and turntable are treated as an integrated whole. This holistic approach extends beyond the cartridge itself to address the entire energy pathway from groove to the first point of amplification.

Selective Laser Sintering of Titanium for GRAVITON® Ti Tonearm

What is the FIN?

The FIN is a tessellated titanium arch, manufactured using Selective Laser Sintering (SLS). Its optimised arch geometry delivers maximum stiffness with minimal mass, while its broad base distributes clamping forces evenly across the cartridge–tonearm interface.

Weighing just 4g, the FIN’s lightweight form belies its mechanical strength. Its tessellated internal lattice enhances rigidity, raising the resonant frequency of the cartridge–tonearm assembly and ensuring a stable, immovable reference platform. The FIN is not merely a fixing component but an integral part of the energy management system, unifying cartridge and tonearm into a single, mechanically coherent and highly damped structure.

A Multi-Material Energy Pathway

The FIN is part of a carefully engineered five-layered interface, each material selected for its specific mechanical properties. Together, they manage energy progressively and prevent resonant artefacts from propagating back into the cartridge:

1. Tessellated Titanium Cartridge Body: Provides an ultra-stiff, semi-open structure, anchoring the generator with minimal resonance.

2. Viscoelastic Adhesive Layer: Fills the tessellated structure of the cartridge body and bonds surfaces while converting vibrational energy into heat.

3. Carbon Fibre Headshell: Helical fibre orientation combines directional stiffness with broadband damping, scattering energy before it can reflect.

4. Cork Energy-Damping Gasket: A natural cellular material that absorbs and dissipates residual vibrational energy at the tonearm interface.

5. Titanium FIN Arch: Clamps the assembly into one rigid, highly damped unit, raising its stiffness and resonance control to reference levels.

The Role of Cork in Energy Damping

Cork is a natural material with a unique closed-cell structure made up of millions of gas-filled pockets. This gives it an exceptional combination of low density, compressibility, and energy absorption. Unlike most materials, cork has a near-zero Poisson’s ratio, so it compresses without expanding laterally, maintaining a stable footprint under load.

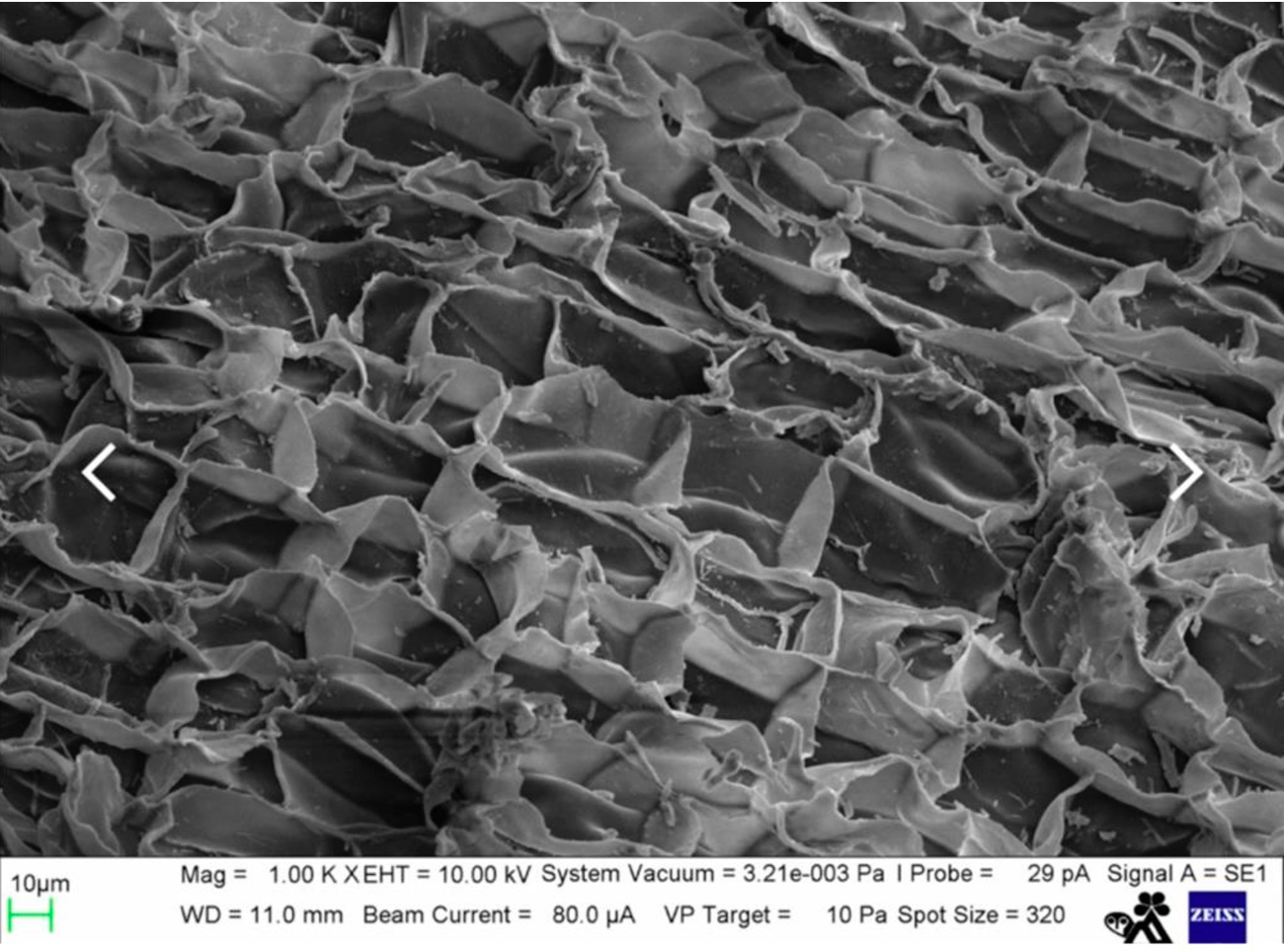

The image below shows a microscope image cork revealling its closed-cell anisotropic structure, with millions of gas-filled pockets that absorb energy along one axis while resisting transfer in others. This natural architecture directly parallels the tessellated titanium geometry and multi-axial carbon fibre construction of the

TESSELLATE Ti Cartridge, where directionally tailored stiffness and damping are engineered to control resonance and optimise energy dissipation at the cartridge–tonearm interface.

This near-zero Poisson’s ratio enables cork to compress without lateral expansion, maintaining a stable footprint. When used at the cartridge–tonearm interface, cork acts as a micro-energy sink, dissipating residual vibration while preserving precise surface contact. Light, stable, and inherently effective at damping, it is the ideal complement to the titanium, viscoelastic, and carbon fibre elements of the TESSELLATE Ti system. Wilson Benesch’s detailed understanding of cork’s behaviour is rooted in extensive research into natural composite materials, conducted in part during the European Union-funded SSUCHY Project, where insights from bio-inspired structures helped inform advanced material applications across the GMT ONE System and TESSELLATE Ti Cartridge.

Read more about the SSUCHY Project here.

Why the Arch?

The arch is one of the strongest structural shapes in engineering, capable of carrying load efficiently with minimal material. In the FIN, this principle is applied to distribute clamping forces evenly, preventing micro-movement or uneven pressure across the interface. Combined with its tessellated titanium construction, the result is exceptional rigidity without excess mass.

An Integrated GMT System Approach

By uniting titanium, viscoelastic adhesive, carbon fibre, cork, and the titanium FIN arch, Wilson Benesch has created a mechanically unified, resonance-controlled platform for analogue playback. This layered approach progressively manages energy at its source, ensuring that vibrational energy is damped and dispersed before it can reach the tonearm or feed back into the cartridge generator.

The FIN is not an accessory. It is a structural component central to the GMT System’s holistic design philosophy — a philosophy that treats every interface in the replay chain as critical. The result is an analogue front-end where cartridge, tonearm, and turntable operate in perfect synergy, allowing the TESSELLATE Ti Cartridge to retrieve and deliver recorded information with unprecedented fidelity.

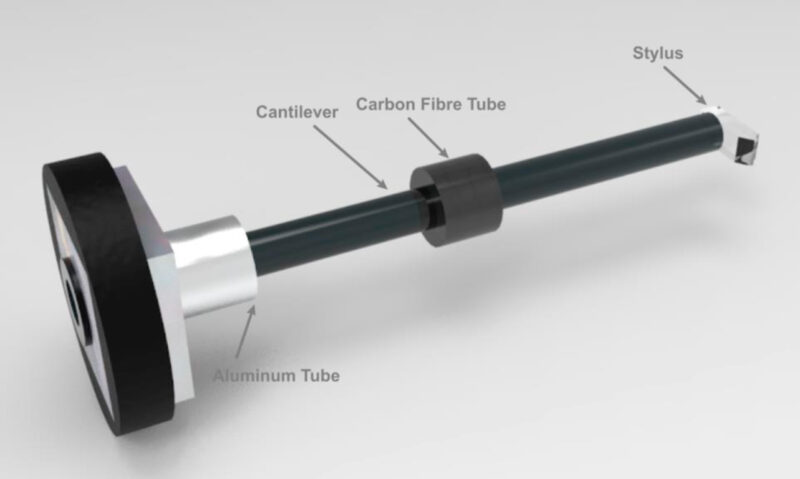

The Hybrid Cantilever Design

The cantilever’s stylus is the first point of contact between the record and the playback system. As the stylus traces the microscopic modulations of the groove, it undergoes enormous accelerations and decelerations, particularly at high frequencies where groove velocity changes rapidly. This makes the cantilever’s design and material selection critical: any flexing, resonance, or instability at this stage will be amplified throughout the replay chain.

The TESSELLATE Ti Cartridge employs a hybrid cantilever design that is unique in the world of analogue audio. The cantilever is made from advanced materials like boron, sapphire, or diamond, chosen for their stiffness-to-mass ratio. These materials provide the rigidity and speed necessary to track groove modulations accurately while keeping the effective moving mass to an absolute minimum.

Selective Laser Sintering of Titanium for GRAVITON® Ti Tonearm

Enhancing this is a U.D. (unidirectional) carbon fibre damping ring, the first of its kind in any cartridge cantilever. Bonded asymmetrically around the cantilever, it adds virtually no additional mass yet introduces significant damping. Vibrational energy travelling along the cantilever is dispersed through the carbon fibre at extremely high speed, suppressing resonance before it can feed back into the generator. This integration of stiffness and damping creates a cantilever that is both ultra-light and tightly controlled.

By combining these elements, the hybrid cantilever delivers unprecedented tracking precision, enabling it to accelerate and decelerate in perfect synchrony with the groove. The result is improved transient response, reduced distortion, and exceptional retrieval of low-level musical detail—laying the foundation for the TESSELLATE Ti Cartridge’s state-of-the-art performance.

Selective Laser Sintering of Titanium for GRAVITON® Ti Tonearm

Additive Manufacturing in Titanium (SLS)

The TESSELLATE Ti Cartridge is one of the first phono cartridges in the world to be manufactured using Selective Laser Sintering (SLS) in titanium—a process that has fundamentally redefined what is possible in cartridge design. Unlike traditional subtractive machining, which limits designers to simple geometries, SLS constructs each cartridge body layer by layer from fine titanium powder. This unlocks complete freedom of form, enabling the creation of highly complex, organically optimised structures with zero material waste.

Inspired by nature’s most efficient load-bearing systems—such as the internal lattice of trabecular bone or the lightweight strength of bird beaks—TESSELLATE Ti uses SLS to realise hollow internal sections, structural honeycomb tessellations, and mechanically optimised anchoring points in a single, seamless titanium form.

The advantages for high-fidelity analogue audio are transformative:

Weight Reduction without Compromise – internal hollowing and tessellated lattices eliminate superfluous mass while maintaining maximum rigidity.

Structural Integrity – titanium’s high specific stiffness ensures that the cartridge body remains inert under the forces imposed by the stylus during playback.

Superior Resonance Control – the internal architecture, paired with damping layers at the interface, suppresses vibrational energy and eliminates unwanted resonance.

This synergy of advanced additive manufacturing and biomimetic design gives the TESSELLATE Ti structural and acoustic performance previously unattainable in any cartridge. Every surface, void, and curve serves a specific mechanical or acoustic purpose—optimised to manage energy, minimise noise, and retrieve the finest musical detail from the groove.

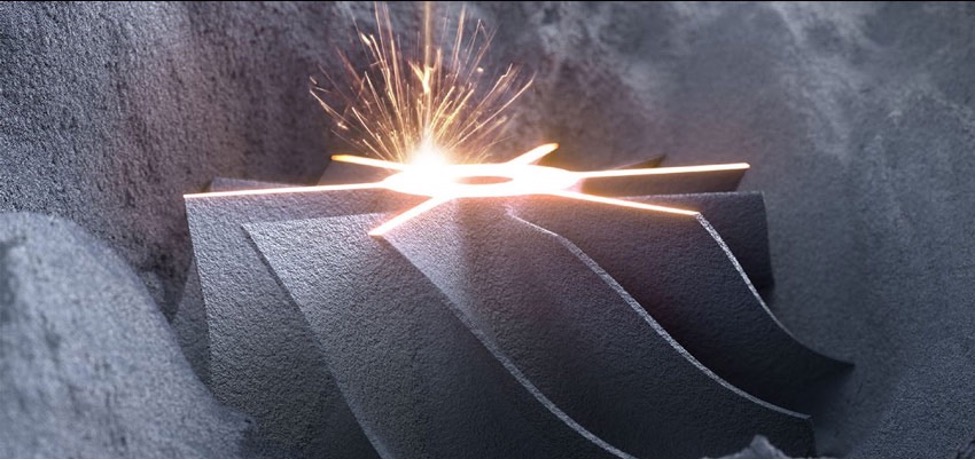

Selective Laser Sintering of Titanium for GRAVITON® Ti Tonearm

Selective Laser Sintering (SLS) in action — Titanium powder is fused layer by layer with a high-powered laser, enabling the creation of complex, organic geometries impossible to achieve with traditional machining. This process forms the titanium counterbalance structures of the GRAVITON® Ti Tonearm and the whole body of the TESSELLATE Ti Cartridge

Leading The New Era of Analogue

The TESSELLATE Ti Cartridge stands as a culmination of more than three decades of research and development at Wilson Benesch, an embodiment of precision engineering, advanced materials science, and a systems-based design philosophy. It brings together the lessons of the world’s first carbon fibre cartridge, the benefits of state-of-the-art additive manufacturing, and a deep understanding of energy transfer in analogue replay systems.

At its core is a titanium body, produced through Selective Laser Sintering (SLS), that achieves a level of complexity, stiffness, and internal damping unachievable by any other means. Its tessellated, semi-open U-section structure represents a radical departure from traditional solid machined forms, optimising stiffness while eliminating mass redundancy. The cartridge not only rejects resonance and reflection but is also structurally integrated with the tonearm through a multi-material interface that includes viscoelastic adhesive, carbon fibre, cork, and the FIN—a titanium arch engineered to clamp and unify the system.

Within the cartridge itself, a world-first hybrid cantilever design combines exotic cantilever materials with a U.D. carbon fibre damping ring, delivering unmatched control over resonance and groove tracing. Every component, material, and surface has been selected or developed for its contribution to vibrational behaviour, energy flow, and mechanical integrity.

More than just a cartridge, the TESSELLATE Ti is a critical component within the Wilson Benesch GMT System—a reference-level approach that considers the cartridge, tonearm, and turntable as one mechanically unified whole. Through this integrated perspective, Wilson Benesch has not only advanced the state-of-the-art in cartridge design but redefined what is possible from the very first point of contact between stylus and groove.

The TESSELLATE Ti Cartridge is, therefore, not merely a product but a testament to uncompromising analogue fidelity. It is the physical manifestation of a design philosophy that refuses compromise, guided by the pursuit of absolute fidelity in the analogue domain.